|

|

|

#1

|

||||

|

||||

|

well, i ran into some problems last night, which may actually be a good thing.

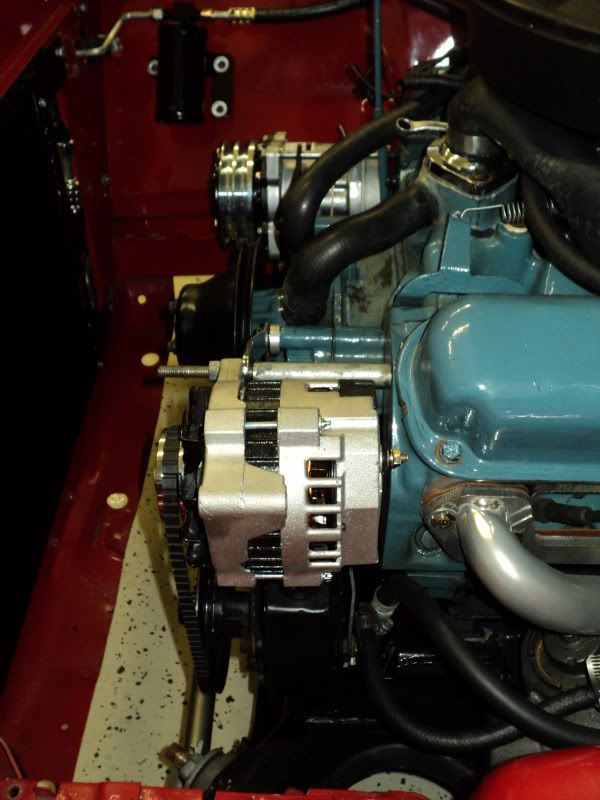

im adding AC to my duster, using a shorty sanden compressor, the classic air kit, and a bouchillon six pack ac bracket. the compressor is trying to occupy the same space as the water bypass outlet port in my victor jr. apparently, there isnt an off the shelf bracket for this setup that WILL clear, so im back to square one. this picture  came up in this thread http://www.forabodiesonly.com/mopar/...d.php?t=150494 this guy is in tasmania, and has done what i have not seen done before. looking at the picture, he is using a drivers side mounted alternator of GM design, and mounted a shorty SD7 where the alternator used to reside on the passengers side. it looks like he used to alternator bracket assemblies to do this, so he could adjust belt tension. only thing i cant tell from the picture is wether or not he has power steering. i do. so that will possibly affect my belt routing on the drivers side. heres what im starting with for this:  i have a spare alternator bracket assembly, so.... it looks like i could use my spare and mount my GM alternator to the same location on the driver side of my water pump. have to adjust for depth of course so i have correct pulley and belt tracking. i would also have to clock it so i could access my power steering pump if it should ever be necessary. so why cant i make this work with relatively little fab work? it looks in my head that this should be an almost bolt together deal, just having to make some spacers, and possibly a tensioner assembly for riding on the back ( flat) of the v-belt. i have seen a few on factory 60's AC belts, but wouldnt know what to look it up under. i think that o ciuld realistically do this. i would have to pick up a 4 groove crank pulley for the extra belt to the AC compressor, though, would the grovves line up with the non AC power steering brackets/pullies? thanks let the ideas, experiences, and "what i thought about/saw/read about's" fly please. and if you have done this deal before, share that too. please. with pictures. michael |

|

#2

|

|||

|

|||

|

i think it sounds doable. just measure two hundred times before you make the brackets.

|

|

#3

|

||||

|

||||

|

The first picture does not have power steering. You can tell from the belts. One feeds the AC and water pump and the other feed the alt and water pump.

You could always go with a serpentine setup from a '90s 5.2l or 5.9l truck. Or does the water pump rotate the opposite direction? |

|

#4

|

||||

|

||||

|

Magnums rotate opposite from LA's. BUT everything swaps. I think you have to use the magnum timing cover.

|

|

#5

|

||||

|

||||

|

so spent a couple hours piddling and raiding my parts bins today. i love having leftovers from all sorts of stuff In my magic bolt bins. Ive got stuff from Honda's, race cars, corvettes, tractors, industrial equipment, etc. so don't ask me what some of the spacer stock came from, cause i REALLY don't know. ill wind up remaking some of it so it doesn't look cobbled together from my magic bolt bins.

but a long story short: the guy from Tasmania's setup will probably work with power steering. i will have to use 4 groove crank pulley and a 2 groove water pump pulley though, due to my edelbrock heads being a little further protruding than his iron heads. i used a spare Chinese chrome alternator bracket swapped around a bit, and located it on the drivers side. lined up perfectly with the existing drilled and tapped hole. had to use a couple of longer bolts, though, as the ARP's just didn't have enough thread engagement. also made a temporary spacer behind the bracket on the upper bolt, as the power steering pump bracket spaced it out too much from the water pump to fudge. this led to some interesting belt routing necessities, as the alternator pulley was now in line with the power steering pump pulley. my solution is to solid mount the alternator above the power steering pump, and adjust belt tension with an idler pulley which also helps route the belt away from the water pump pulley where it would otherwise rub. the idler is actually an AC idler assembly from a d-series Honda motor from a CRX i built three times. on the AC pump side, the compressor fit well once i removed the radiator fans as the motor on the one was contacting the compressor clutch. i also had to remove my previously fabbed fuel pressure regulator (that was leaking from the mechanical fuel pump block off plate) so i could tuck it in some more. i believe that with the AC style pulleys, i will have a good belt routing for this one as well. and now the interesting stuff, the AC compressor/brackets. mind you, its nowhere near finished, but more of a proof of concept thing. let me know if you see potential issues.        more later when i have some more time. need to build a wiring harness for a mobile soda blaster in the next couple of weeks, then thrash on this car to get ready for RTTH. |

|

#6

|

||||

|

||||

|

That belt is going to have a rather short life expectancy. It wasn't designed to flex in both directions. The grooves in the serpentine idler will also cut down of the life of the belt.

|

|

| Thread Tools | |

| Display Modes | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Small Block, (340) AC Brackets | Furylllguy | Parts Wanted | 0 | 09-12-2013 06:37 PM |

| 1984 ramcharger accessory brackets | rick1984 | Ram Truck Chat | 24 | 09-03-2006 04:23 PM |

| brackets on small block 360 | Boostforlife | Performance Talk | 2 | 04-13-2003 09:07 PM |

| Big Block Truck engine brackets | MoJoe | Performance Talk | 2 | 05-21-2001 02:05 AM |