|

|

|

#1

|

||||

|

||||

|

Hi, I thought I'd up date my build, a 511" 70 Cuda . After two years of asking dum question I've spent the last year buying parts and I've got all of the major parts for the build, with the exception of the front suspention. I'm leaning towards the AlterKation k member.

Here's the pieces for the 511" and what's happening with it. On Monday I'm starting to clearance the block for the rods and throws. As soon as the bearings get in I'll figure my deck height and take the block in to be decked and put together. Block- it has a partial fill to the top of the frost plugs, lifter bores trued and bushed. bottom rail and main caps have been decked for a girdle, I'' try to post a piture. It will be 0 decked. Crank-Billit Keith Black 4.25" stroke, used but unturned, no nitro 0 cracks. Rods- 7.135" R&R Aluminum, 2.375". Pistons- Bill Miller, coated. Pins- Bill Miller taper walled, 157 grams. Cam- Straightline, solid roller,.688 intake, .666 exhaust, .267/278 @ 50 cut away Competion Cams lifters, with offset pusrod location. Rollmaster timing chain. Heads- Indy 440, they are at Indy getting a full port and polish and 2.25 valves. Rockers are Indy 1.6, but I think I'm going to get a set from Harland Sharp. Springs are Isky Gold Stripe, 275# on the seat and 640# at the nose. I picked up my 727 yesterday, $5100 with out the convertor.  Next week I'll remove the doors, front fenders and interior and start putting in the Art Morrison 10 point cage. It's bent for a stock interior. My wife has the camera on vacation for a couple of weeks but if there is any intrest in it, I can post pitures as I go along. I know I'll have lots of questions, I'm replacing the complete power train, cooling system, brake system, and fuel system. I'm keeping all the origanel parts so it won't be hard to return it to the way it is now. Thanks |

|

#2

|

||||

|

||||

|

Here's the parts, I replaced the lifters, in piture with the cut aways.

|

|

#3

|

||||

|

||||

|

This is the girdle and the aluminum caps.

|

|

#4

|

||||

|

||||

|

Toad,

One thing you'll run into with the 1/2" crank when clearancing is you'll wind up grinding a fair portion of the oil pick-up tube boss away. You may already be planning on an external line oil pump, just didn't see it mentioned. I had a similar bottom end setup in my old altered, ran 8.30's at 157 loafing at 6700 through the traps with 915 steel heads, had enough torque to pull trees down. Think you'll like it, glad to see someone doing something beside the usual cookie-cutter stroker setups. |

|

#5

|

|||

|

|||

|

Good job....Keep us posted and (Yes) picture Please.......

|

|

#6

|

|||

|

|||

|

Why so much for the tranny, Paul.

|

|

#7

|

||||

|

||||

|

In spite of what one would think, it wasn't that hard to do.

We started with an empty case and filled it with parts from http://tcsproducts.com/components/co...c22c3ec96c.jpg and a transbrake and 6 bolt ultimate sprag from A&A. The planataries in the link are pricey, I went with the 4 pinion. Then hardend shafts, billit steel front drum, ally rear drum and a bunch of other aluminum pieces. We also put a Bottom Feeder swinging pickup and pan on it. I know it's overboard but I wanted it to be as close to bulletproff as I could for the HP I'll make. |

|

#8

|

||||

|

||||

|

I got my heads back from Indy. I had them do a full port and polish, cut for 2.25 valves and cnc the cumbustion chambers. These are older heads so they couldn't do the full cnc porting, They did the first 3 stages with the cnc and finished by hand. The heads had bowl work done on them from new so I'm not sure how much metal was removed, but it doesn't seem like much, mostly blending.

At the top of the piture is the manifold that was port matched to the heads before porting. You can see the difference in the thickness of the web between the ports, it seems that the same amount has been taken off each side, I'll check that when I match the ports on the manifold. (TURNS OUT THAT NONE WAS REMOVED ON THE SIDE OPOSSITE THE WEB) The floor is pretty much untouched and there's about .100 off the roof.  There's alot off work done around the valve guides, much more of the guide is exposed and the web support is very sharp. it was about 1/4" wide before. There has been quite a bit removed between the plug and exhaust valve.  Exhaust ports are open a little, most of the work was around the valve guides and bowl, the bowls already had work on them form Indy when I got the heads, it doesn't look like much more was done to the bowls, mostly polishing.  Mr. T- Thanks to a heads up from you a couple of years ago I do have an external oil setup. I.m grinding on that right now. I'll take some before and after pitures of it and any other areas that I have to grind. The ally rods have 440 journals, 2.375". |

|

#9

|

|||

|

|||

|

HEY toad490. I see you're running a roller cam. If the cam is over a 600 lift, I'd advise to switch rockers. I've snapped 4 sets, well either #4 or #5 exhaust. One at a time one or the other. I found out that INDY is using T&D rockers for that kind of spring pressure. I haven't used T&D but, that's what I found out (I went to a HEMI). You still thinking on alter-k-tion??? Well, I have one and it's the first thing I bought in a long time that I did NOT have to modify to get it to fit. IT IS OUTSTANDING. mpracehemi

|

|

#10

|

|||

|

|||

|

Indy rockers are made by Dove, Dove makes rockers for many "rocker brands". In my street & strip use, the first breakage was after four years with a little under 0.7" lift roller. I asked Ken Lazzerri about them, and he told that those rockers ahve a life span that is about 3-4 years in that kind of use and stress. The later two sets lasted three years, I always renewed the whole set when one broke. Last time I went with Erson rockers, they should last "forever" with under 750 lbs open pressure, and were priced in between the doves and T&D/Jesels. They are a stout rocker, but unfortunately they don't make them anymore. I had one adjuster come loose of them (own fault), and the pushrod ate itself almost through the rocker. It's kind of fixed, and worked through the end of the season, but I have been looking for a new set. T&D's rockers with a common shaft and regular oiling for 440-1 heads is #8210, and was 924.11$ the last time I asked directly from T&D. http://www.tdmach.com/

|

|

#11

|

|||

|

|||

|

Dear dartgt66, I was running a 720 lift (1.6) cam with 785 lbs open pressure and my first rocker failer was under 75 miles, replaced set and they lasted about the same, two more sets later and I called jesel, then T&D. They told me Indy was selling they're rockers for people like me who was running a bigger cam/open pressure set up. I never tried the set up because I switched to a HEMI. A guy I know traded me my wedge for everything but the block for the HEMI. I ended up buying new rods, pistons and a bigger cam for what hp I wanted to achieve, the heads are STAGE V. Heads have been massaged , they aren't the millinium heads, but they still flowed out to 535 @ 750. My motor dynoed at 948 hp @ 6500 rpm's with 812 ftlbstq @ 5100, not bad, but I was shooting for over 1000 hp. I was just trying to save toad490 some grieve by my experience, like everyone else, I like helping people from what I know and have gone through.

|

|

#12

|

|||

|

|||

|

I never measured the open pressures in our heads, but guess they were about 700 lbs open. Comp cams 944 springs. If in doubpt, it's a good idea to go with better rockers in the first place, a rocker breakage may cause big damage.

|

|

#13

|

|||

|

|||

|

My last rocker failer ended up damaging one of the main bearings and somehow scratched one of the cylinder walls, requiring boring out .030 to clean it up. See, the rocker that failed caused the push rod to mushroom and the fragments from the pushrod to do the damage. Luckily, I already did the swap but, I did offer the guy to help pay for the cost difference, he did know the rocker failed, he was there at the track when it happened. Any how, it is always better to buy the best parts you can when you're racing or you could end up spending alot more later.

|

|

#14

|

|||

|

|||

|

You keep that crank rolling around on the floor??

|

|

#15

|

|||

|

|||

|

Toad,

So how are thing going??????

|

|

#16

|

||||

|

||||

|

Hi Racer, Life has gotten in the way over the last few weeks and I haven't done much on the car its self, mostly I've been getting the locations and the plumbing for the radiator, tranny cooler, fuel system, oil cooler, external oil lines, remote oil filter and oil accumulator. this is not as easy as it sounds. Hoses and fittings take up room!

As far as the engine goes I've ordered a set of 1.7 rockers from T&D. They have them from 1.5 to 1.7 ratios in .5 increments. The 1.7s will give me .731 lift, 1.6s are .688 lift. Depending on how long it takes for them to get here and how busy the engine builder is, the engine should be done in 3 to 4 weeks. I'll post some pitures of what I've had to grind on the block for the 4.25 crank and 2.375 ally rods. |

|

#17

|

||||

|

||||

|

Of course not, I kept stubbing my toe on it.

|

|

#18

|

|||

|

|||

|

Hey toad, I know how life gets to be obstructions, the wife & I lost one of dogs (our kids!!!, we have no human kids). She developed a heart condition and within a month she past, we are still grieving, had the girls for 11 yrs., still have the "enforcer" (pit bull mix). She's still expecting/looking for the other, it's been a week tomorrow.

Anyways, life goes on. I've been working on a new friends '68 'Stang, getting parts together so I can install the 428 CJ. Although it's not a MOPAR, it's a beautiful car. The guy has had bad luck with others who cliam to work on the car when actually it just sits and they get prepaid for the job. I want to do the job correct for the guy, show him that there is honest people still around. Next week (feb. 21), I'm taking my car to the strip. Still trying to get my 60 ft. down, right now it's 1.35. I think I can get it down, just a little more adjustments on the ladderbars. Later, mpracehemi |

|

#19

|

|||

|

|||

|

Hi toad, I forgot about your purchase of T&D rockers. You'll be glad you went that route, thy're better in quality/strength, plus the way you went, you have a larger cam.

Later, mpracehemi |

|

#20

|

|||

|

|||

|

Interesting to see how long it takes to get the T&D's in reality. Sometimes they are pretty slow. I think we will go that route too after finishing our current rockers.

|

|

#21

|

|||

|

|||

|

Glad to see you are going to the T&D rockers. I don't mind using Harland-Sharp stuff in flat tappet motors..Roller cammed stuff needs T&D's for realibility...I have seen to many bad explosions from rocker arms failing..

Looks like to me you will have a nice motor when done..Should be 700-Hp motor. What stall is the converter? what gear are you running? BEST OF LUCK!!!!

|

|

#22

|

||||

|

||||

|

Quote:

Here's some pics of the grinding I've had to do for the rods to clear. [SIZE="4"]This is the internal oil picup area. I had to JB weld a solid plug in it, then grind into the plug.  This had to be done to one side of each cylinder.  It's hard to see but it also took some grinding on the bottom of each cylinder on the camshaft side.  The bad news is the cam and rod interfere. I'm going to have too hook up the timing chain and cross my fingers. If not I'll have to take some off the rods. 2.2" journals are looking pretty good right now..... |

|

#23

|

||||

|

||||

|

Quote:

They will hit unless the chain is on and timed right, looks like a standard to small base circle cam, you should be alright. What kind of rods are you running? |

|

#24

|

||||

|

||||

|

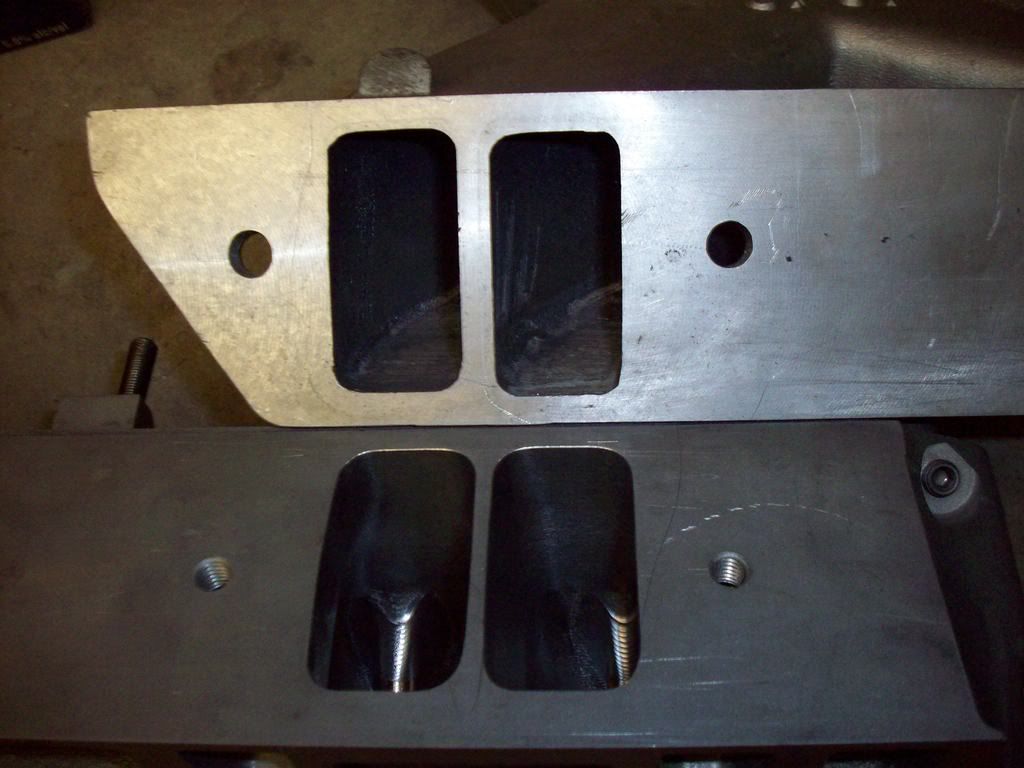

[SIZE="4"]That's good news on the cam clearance. I'm using R&R rods, 7.1inches. The mating surface is kinda neat. Thats some assembley lube in the grooves.

|

|

#25

|

|||

|

|||

|

Lotsa good pix, toad. I think you have done your home work..and you are not sparing any expense to do the job right...that is comendable!

Is your car a ladder or 4 link? sorry if you already answered this. |

|

#26

|

||||

|

||||

|

Quote:

I started doing the intake/port match, on the heads should I blend corners of the port with the gasket?  I didn't have any dye so I used a red Sharpie to show what needs removed on the intake. How far back should I go?

|

|

#27

|

|||

|

|||

|

I'm still waking up, but it looks good. If the head port were larger than intake, then you would still need to do some more massaging, as long as the flow has nothing to stumble on going into the heads, you're good to go.

I know the money is hard come easy go, but wait til you step on that throttle, it'll be well worth it. Then, you'll be kicking yourself for not going bigger. |

|

#28

|

|||

|

|||

|

Quote:

http://chucker54.stores.yahoo.net/lespsl.html Sounds like they are the way to go..makes sense to me anyway...thought you might be interested. i would be too if mine rear end was'nt already all set up with the Tri City Launchers. |

|

#29

|

|||

|

|||

|

toad, before you buy the caltracs set-up, look to see what hp you're sitting at, go to other cars that how around the same hp (in the range of) and see what they did suspension wise and ask them how they're hooking up. Is you're car mini-tubbed or stock wheelwells? I know from my own experience that I'm going to want to go faster and faster, so I bit the bullit and backed-halfed my car, skipping mini-tubbing and the expence. Yeah it's going to cost but buying the caltrac is around $800, buying ladder bar set-up and coil over shocks is around $950 from chassisworks (the double adjustable), if you're still stock right now and go ladder bars, in the future just buy new brackets ($50) to move the bars inward on axle housing. What I'm trying to say is why stay with leaf springs when ladderbars work so much better (more adjustability) especially with more hp than what the leaf springs were designed to handle. Just do some more research, checking on other cars (MOPARS). I did my research to what I wanted and did the work myself, and to a couple of other guys cars. They stayed with they're mini tubs and went ladderbars. It's not hard if you can weld, measure and use a square. If you want more info., just ask. I'll be happy to help.

|

|

#30

|

||||

|

||||

|

I'm kinda between a rock and hard place, the car's worth too much for me to do much more than what I've done. I moved the springs inboard 3 inches and it seems to have a small mini tub. I have 12.5" M T Sportsmans on it now with no problems. I'm not going to make any decisions on the suspension until I've finished the engine.

A very good friend for more than 25 years and my drywall partner for 12 years, is in his last few months and he asked me too get it on the road so he can have a ride in it. No pressure there eh. So its not going to be as together as I would have like it to be when I put it on the road. The rearend and suspension will have to wait. |

|

| Thread Tools | |

| Display Modes | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| My 70 Cuda 511 Build | toad490 | Drag Racing Forum | 0 | 10-27-2009 03:17 AM |

| Where can I find Build #'s for 74 Cuda | Wicked_ss | Vintage MOPAR chat | 1 | 12-10-2003 09:08 PM |

| I'm starting to build my 'cuda... Suspension first! | Eternalfootman | Performance Talk | 6 | 12-05-2002 10:03 AM |

| Fastman's "special Build" TB | 98ramss/t | Ram Truck Chat | 5 | 08-28-2001 07:20 PM |

| "The perfect 360 L. A. series build-up" | bebo1018 | Ram Truck Chat | 4 | 03-08-2001 10:33 PM |